FIELD SERVICE DIVISION

Bennett Electric incorporates a special field service division to address on-site problems that may occur. Trained technicians use the latest available equipment to aid in diagnosing and further preventing problems. Predictive maintenance programs help to minimize downtime by red flagging potential problems. Fact is that this new trend is the way to the future. Several different services are offered depending on the application. Read on further to see what application applies to you?

There are three types of equipment maintenance:

- Run-to-failure, or better known as fix it when it breaks

- Preventative maintenance, which is time based (monthly or quarterly etc.) and often leads to unnecessary component replacement and added expenditures.

- Predictive maintenance, which is based on the operating health of the equipment. Potential problems are headed off and corrected before a major problem occurs. Some methods implemented include infrared thermography, vibration analysis, oil analysis, and various software applications to chart the progress.

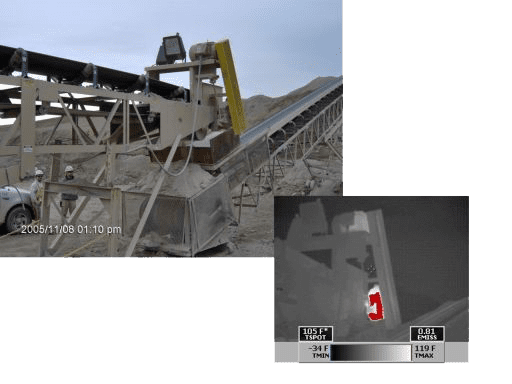

Infrared Thermographic Scans

Infrared thermography used in predictive maintenance programs is commonly used to test electrical systems, buildings, roofs, and mechanical systems. This effective, non-destructive process aids in improving manufacturing processes, and assists R&D development. Bennett Electric offers a Radiometric 500DX camera to capture, organize and process images to diagnose anomalies in many applications. Save time and money, prevent catastrophic failures; see beyond what the human eye cannot.

Laser Alignment

Ensuring that a machine is properly aligned plays a critical part in efficiency and life expectancy of the machine. Wear and tear on couplings, seals and bearings can be significantly reduced. Energy consumption, noise, and vibration are also significantly reduced.

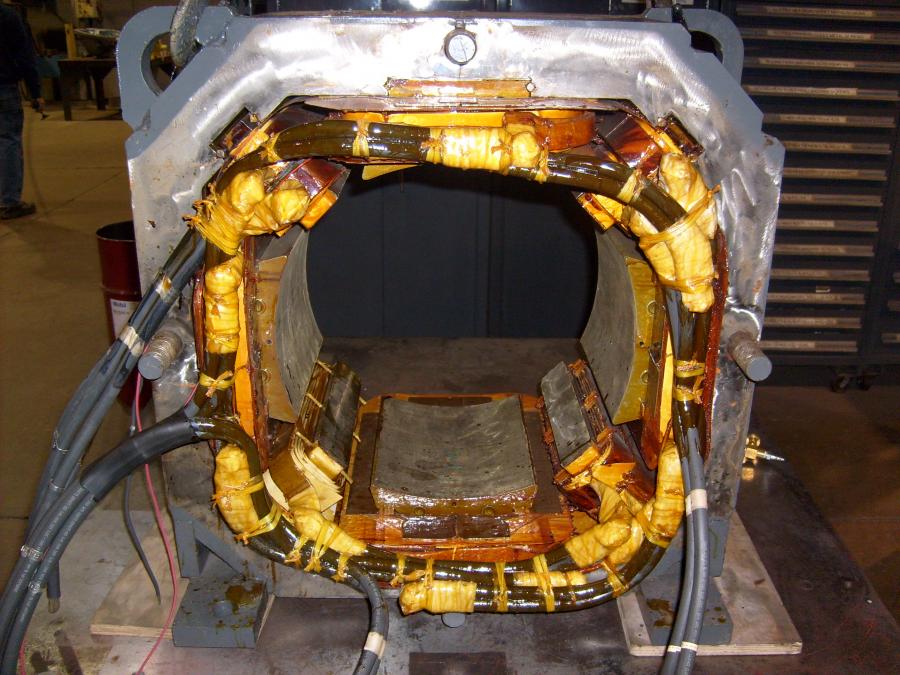

Vibration Analysis

Perhaps the most important part of predictive maintenance deals with vibration issues. Vibration is often overlooked, yet can lead to catastrophic results. By the time vibration is noticed, structural integrity of the machine is compromised. Correcting the problem at this level is crucial, but counterproductive. Vibration analysis is used to trend premature wear and plan downtime.

As an added benefit, studies have shown average return rates from 7 to 1 to as high as 35 to 1. For every dollar spent on predictive maintenance programs, a company can save between 7 to 35 dollars. Along with the added benefit of saving money, you can utilize plant equipment and personnel more efficiently; equipment will last longer leading to breakdowns becoming non-existent.

On-site analysis of problematic machines is available through Bennett Electric. Trained technicians use the latest available equipment to diagnose and repair problems that may occur. Motor circuit testing along with fluid analysis is further used to test the health of a piece of equipment. By implementing these programs long-term reliability is enhanced.

Bennett Electric has decided to yet again raise the bar by incorporating the latest technology and equipment to better serve industry. Jump on board with Bennett Electric, sit back and enjoy what life has to offer.